PRODUCTS

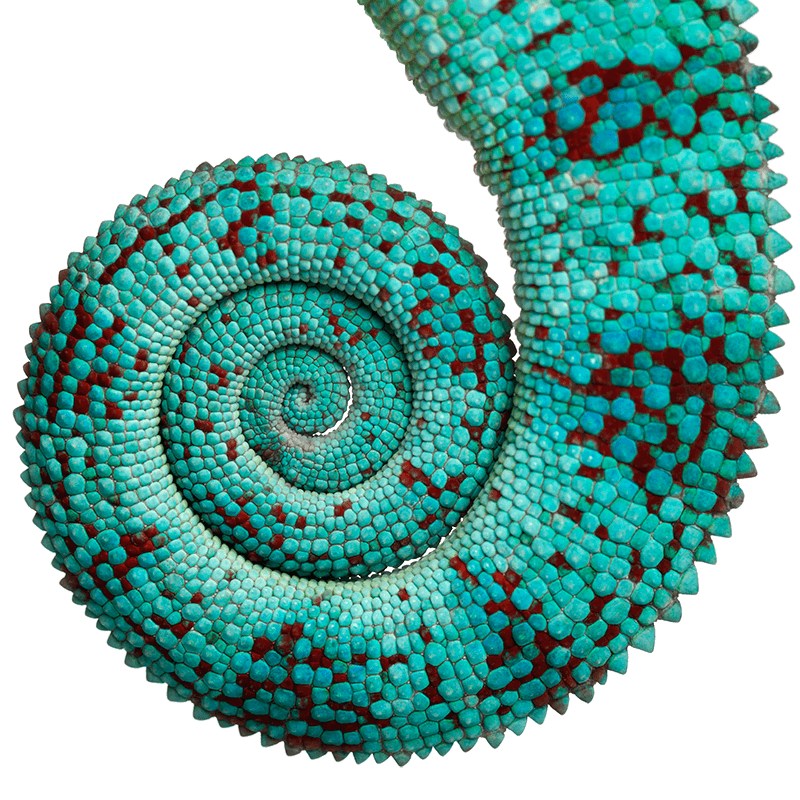

COMMUNICATES ITS EMOTIONAL STATE

CONCEPT

_

the chameleon is the symbol of TDA products made of Arock® and available in 48 natural colors. The chameleon uses the mutation of its natural colors to communicate every mood. TDA uses 48 natural colors in the production of Italian design artifacts giving it the distinctive value of obtaining the same result in the different materials: wood, aluminum, and Arock®. Producing shower trays and shower enclosures, furniture and accessories

SUSTAINABILITY

_

RECYCLING

it's an eco-sustainable process that allows to transform waste into reusable resources in other contexts avoiding waste and safeguarding the environment. The materials for the production and packaging of TDA products are part of this system. Once disposed they are reused in alternative forms

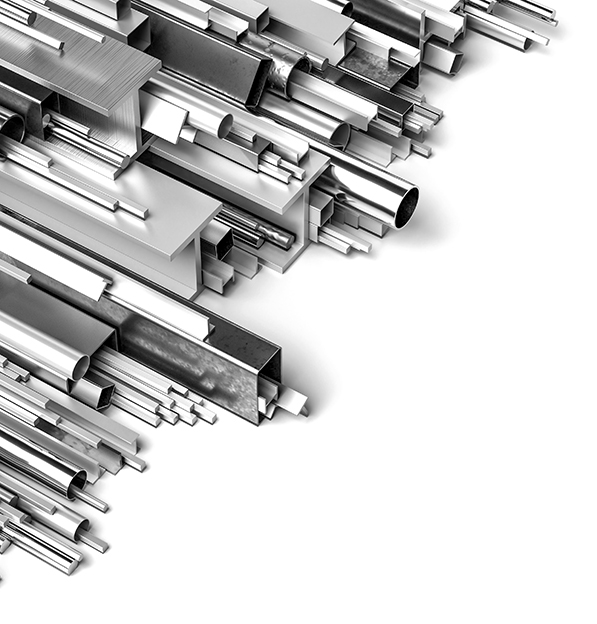

it has optimal characteristics for recycling. It can be 100% recycled and reused indefinitely, to give life to new products every time. The profiles discarded from the production cycle are delivered to certified companies that deal with the recovery of the material that is recast for the production of secondary aluminum billets for industry. Regulation (EU) 333/2011 lays down the criteria according to which certain types of scrap of iron, steel and aluminium cease to be considered waste in order to be re-produced

Given its nature it can be recast countless times, allowing significant energy and raw material savings. The glass waste is transferred as scrap, purified and introduced into the production cycle of a new process, starting from a 10% of the weight of the dough to almost replace the other primary components. The glass at the plants is complete with documentation in accordance with the authorizations and procedures drawn up in accordance with the environmental management system certified in accordance with UNI EN ISO 9001-14001

Cardboard is used for the packaging of shower enclosures, shower trays and TDA furniture. The scraps and waste are given a second life since the cardboard/paper is a recyclable material, since the cellulose it contains can be subjected to repeated processing cycles. Its recovery can be treated for the production of new pap

the recycled material obtained is of excellent quality. The wood waste is collected at the appropriate platforms and then sent to the recycling plants where it is processed until it re-enters the production cycle in the form of new elements for the industry. The consignor produces, with the waste material (wood) TDA, a new product certified FSC and PEFC, standards that ascertain the controlled origin of the product from well-managed forests, controlled sources, recovered materials or a set of these sources

a necessary process to optimise energy use and minimise the impact on climate and the environment. To contribute to environmental sustainability, TDA uses different solutions and technologies

ENERGY EFFICIENCY

Energy-saving lighting systems with LED lamps are installed in TDA production halls, for interior, exteriors, and production departments. This leads to low energy consumption and savings in terms of electricity taken from the network

The heating systems of TDA production departments are made with low temperature radiant panel systems to ensure the comfort of the environment and the workability of the product despite harsh climates. In addition, this system allows a low consumption of methane gas with consequent CO2 emission into the atmosphere

The lighting in the company follows precise logic dictated by control systems based on production needs and optimized, according to the seasonal cycle. This reduces the waste of electricity. Thanks to an intelligent management of systems and devices, it is possible to optimize their use, ensuring a reduction of expenses and energy

the company plans to build almost 300 kW of photovoltaic system on the roof of San Gervasio plant, in order to meet its annual needs, contributing to the Green conversion and addressing the path traced in recent years by the Kyoto Protocol and the G20 towards the ecological transition of the planet